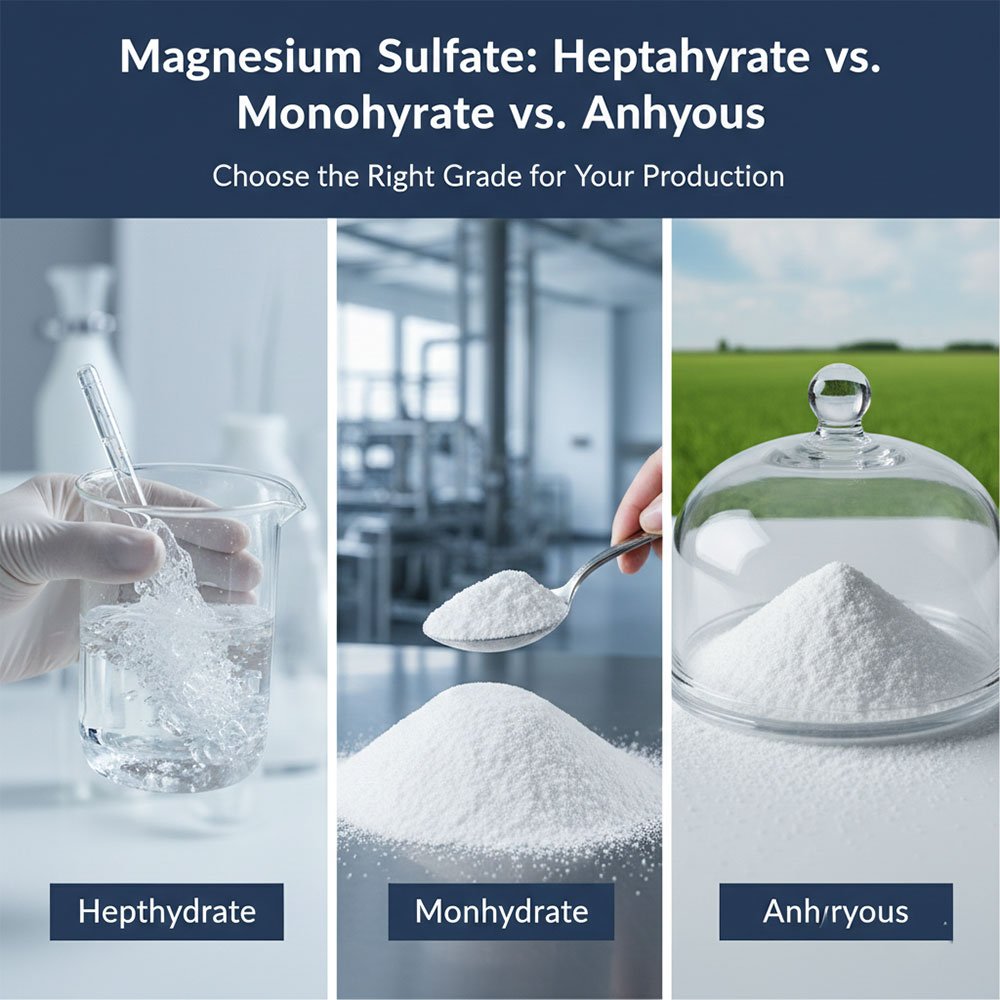

Product Overview

Magnesium Sulfate (MgSO4) is a versatile inorganic salt widely used across agriculture, industry, and pharmaceuticals. However, choosing between its different hydration states—Heptahydrate (MgSO4·7H2O), Monohydrate (MgSO4·H2O), and Anhydrous (MgSO4)—is critical for production efficiency. These variants differ primarily in their water content, which directly impacts their magnesium concentration, solubility, and physical stability.

| Specification | Heptahydrate (MgSO4·7H2O) | Monohydrate (MgSO4·H2O) | Anhydrous (MgSO4) |

| Appearance | Transparent Crystals | White Powder/Granular | Fine White Powder |

| MgO Content | ~16% | ~25-27% | ~33% |

| Solubility | Very High (Quick Dissolve) | Moderate | High (Exothermic) |

| Stability | Tends to lose water (efflorescent) | Very Stable | Highly Hygroscopic |

| Main Advantage | Aesthetic & Fast Dissolving | High Nutrient Density | Highest Purity/Drying Agent |

Application Scenarios

1. Agriculture and Fertilizers

- Heptahydrate: Preferred for liquid fertilizers and foliar sprays due to its rapid and complete solubility.

- Monohydrate: Ideal for compound fertilizer (NPK) blending and soil application because of its slow-release properties and high magnesium density.

2. Industrial Manufacturing

- Anhydrous: Primarily used as a drying agent in organic synthesis or in specialized construction materials (cement) where water content must be strictly controlled.

- Heptahydrate: Widely used in the textile industry for fabric weighting and in the paper industry for bleaching pulp.

3. Personal Care and Detergents

- Heptahydrate: Known as “Epsom Salt,” it is the gold standard for bath salts and cosmetic formulations due to its skin-friendly crystal structure.

Key Product Advantages

Logistics Cost-Efficiency: Monohydrate and Anhydrous forms have lower water weight, significantly reducing international shipping costs per unit of active Magnesium (MgO) compared to Heptahydrate.

Versatility in Processing: Whether you need a quick-acting liquid solution (Heptahydrate) or a stable dry premix (Monohydrate), there is a grade tailored for your specific equipment.

Strict Quality Control: WoheChemical ensures all grades meet rigorous industrial standards, minimizing heavy metal impurities and ensuring consistent particle size distribution.

Usage Guidelines and Safety

Handling Anhydrous Grade: Always handle Anhydrous MgSO4 in a dry environment. It is highly hygroscopic and will clump or revert to Heptahydrate if exposed to humid air.

Exothermic Reaction: When dissolving Anhydrous Magnesium Sulfate in water, be aware that it releases heat. Add the powder slowly to water to manage the temperature.

Storage Conditions: Store all grades in a cool, dry, well-ventilated warehouse. Keep bags tightly sealed to prevent “caking” (clumping), especially for the Heptahydrate grade in humid climates.

Frequently Asked Questions (FAQ)

Q1: Can I replace Heptahydrate with Monohydrate in my fertilizer formula? A1: Yes, but you must adjust the dosage. Since Monohydrate has a higher MgO content (approx. 25% vs 16%), you will need less material by weight to achieve the same nutrient levels, which often saves on storage and transport.

Q2: Why is Magnesium Sulfate Anhydrous more expensive than the crystalline form? A2: The price reflects the intensive dehydration process required to remove all water molecules from the crystal lattice. However, for applications requiring a desiccant or maximum purity, it is the only viable option.

Internal Link Suggestions

Contact WoheChemical for Bulk Pricing and Samples

Industrial Grade vs. Agricultural Grade Magnesium Sulfate: What’s the Difference?

Explore our Magnesium Sulfate Heptahydrate Technical Data Sheet